How Health Companies Are Leveraging Manufacturing Analytics

Data is becoming increasingly important when it comes to running your business effectively. From helping you understand or predict sales trends with your customers to measuring success each quarter, data is invaluable when it comes to gaining a deeper sense of how your business is doing. An analytics dashboard, especially, is a useful tool for quickly visualizing different factors in your manufacturing process and providing you with insights about your performance. This is why more and more industries are finding data analytics an important branch of the work they already do.

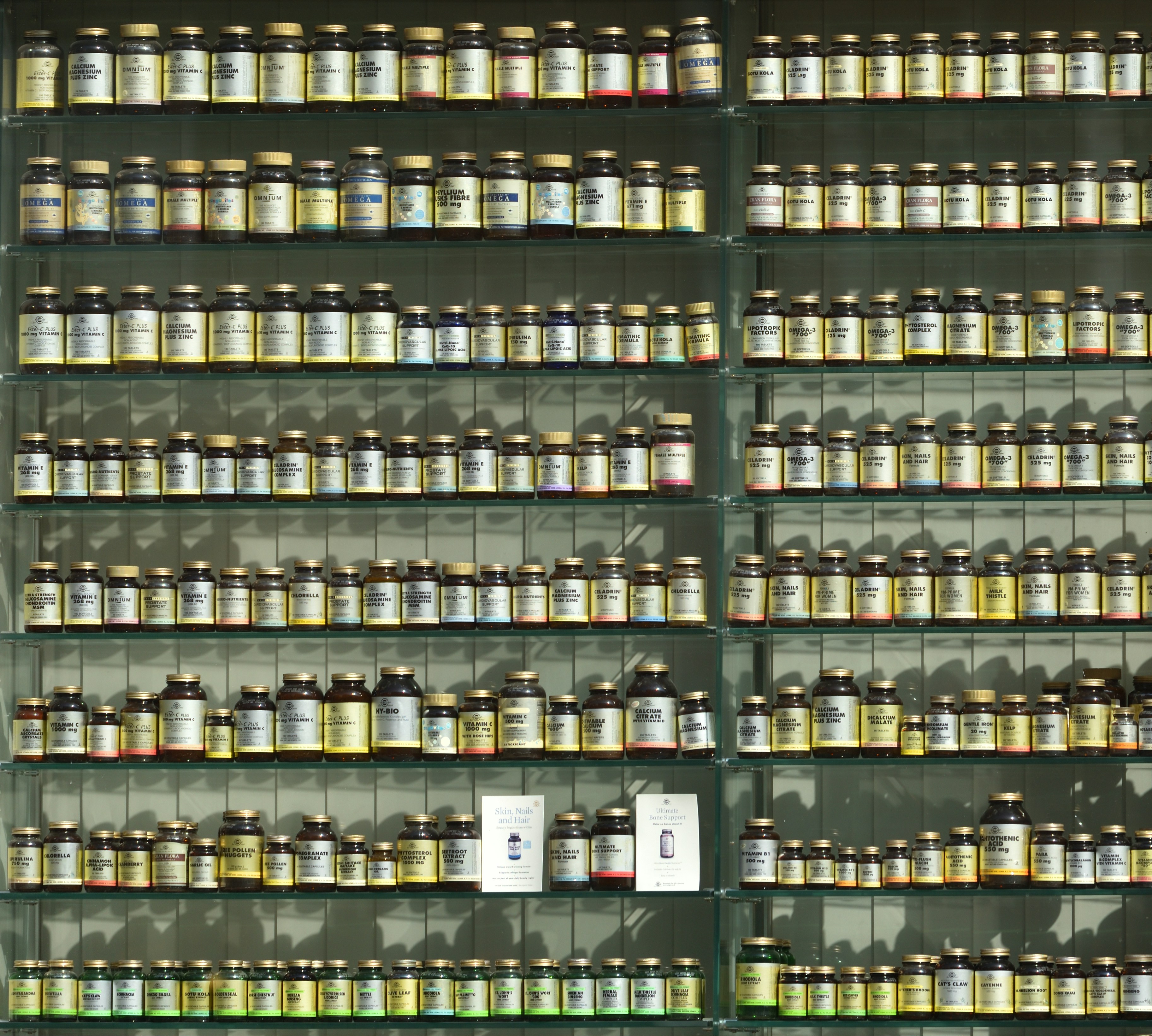

One industry that can find data analytics particularly useful in the field of health and wellness. As you may have recently read, the health and wellness industry is booming thanks to an increased emphasis on physical and mental wellbeing during the COVID-19 pandemic. As such, companies focusing on mindfulness ebooks and private label supplements are finding value in implementing an analytics solution. For example, predictive analytics tools can be particularly useful for planning downtime or analyzing your supply chain, data that gets even more rich with years of experience in the sector. Here are just a few of the other ways that health companies are leveraging manufacturing analytics to improve their business processes.

Manufacturing analytics can provide consistent quality.

Especially in the wellness industry, consistency is key. If you don’t have high-quality products that customers can count on day in and day out, you might as well get out of the business. For example, the best private label supplements or vitamins are revered as such due to the fact that they provide their users with the appropriate nutrients each and every day. Manufacturing analytics offers a few ways for your business to prioritize manufacturing and packaging high-quality products. For example, using big data and IoT devices, it’s possible to ensure reliability and monitor quality assurance in real-time. In the case of a problem with your product line, manufacturing analytics can also help you assess where the point of failure was, whether it was in formulation or transportation to your shop floor. This makes certification and consistency in product quality much easier for any nutritional supplements company looking to gain an edge in the manufacturing industry.

Manufacturing analytics help you improve your supply chain.

Manufacturing analytics solutions are also a powerful way to gain new insights into your supply chain. Especially if you’re sourcing materials from throughout North America, big data analytics can help you evaluate whether or not you’re getting the best price on your packaging, capsules, or raw materials. Real-time data offers you the opportunity to better handle how you manage orders, while also giving you insights into other aspects of the entire process. For example, you can use predictive analytics to forecast demand and leverage business intelligence and advanced analytics to evaluate how your suppliers are performing in terms of fulfillment and efficiency. All of this helps you maximize your supplement business’ input and output strategies.

Manufacturing analytics offers you insight into your suppliers.

As was mentioned previously, the insight you can get about the suppliers you use from big data can be indispensable. Especially if you’re a business that thrives from on-time delivery and needs real-time insights, knowing that your private label supplement manufacturers are hitting their benchmarks can be crucial. You may, for example, realize that soft gels are being routed much more quickly than your gummies, which can help you better allocate your resources and energy to fulfilling those orders when they come in. Ultimately, having the ability to reference all of these sorts of takeaways can help you improve your bottom line each quarter.